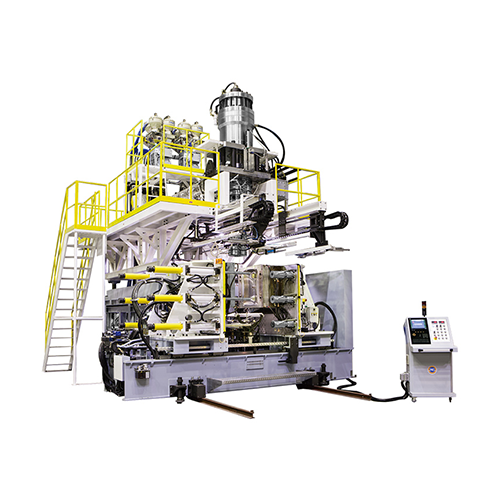

Automatic-Blow-Molding-machine-L Series

Categories : Automatic Blow Molding Machines

Full Shine's L Series Blow Molding Machines are suitable for producing big and large containers, such as water tanks, chemical drums, jerry cans, and automobile components. These machines are equipped with accumulator-type mold heads and multi-point parison controllers. Mold carriages are perpendicular and easy for producing different-shaped products.

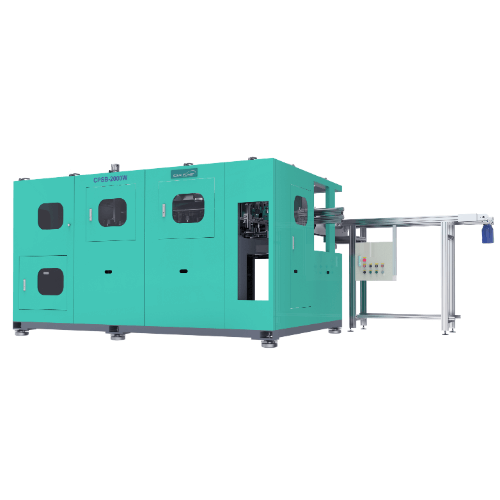

Large Volume PET Blow Molding Machine-W/L Series

Categories : Automatic Blow Molding Machines

Large Volume PET Blow Molding Machine-W/L Series Robust hydraulic clamping.Double robotic arms for speedy preform loading.Cost Effective machine that is also easy to maintain.Compact structure for small floor foot print.Modular design for easy maintenance.

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

Medium Co-extrusion Blow Molding Machine

Categories : Electric Blow Molding Machines

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C is the most popular choice for the edible oil export countries, production ranges from 5L to 30L jerry can. The outer and inner layer composed of 15%-20% virgin material and master batches. The middle layer can put around 60%-70% cost effective regrind material and also can add CaCo3 (no more than 30%), which can reduce cost down to 10-12% material cost. By contrast, the single layer jerry can only add around 5%-7% CaCo3 which has no evident improvement over material savings. Chen Way CWM

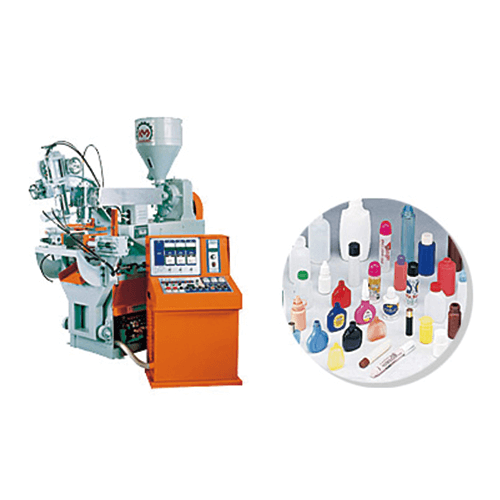

Fully Electric Co-Extrusion Blow Molding Machine (Dual Diehead & Double Station / Visi Strip)

Categories : Automatic Blow Molding Machines

Chia Ming has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is a total new innovative design with servo motors controls which significantly reduce energy consumption, give higher production rate, noise level much reduced, in long term total production cost being dramatically reduced.

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

PET Automatic Stretch Blow Molding Machine for Small Mouth Jar/Container

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideally suitable for applications where stringent quality requirements have to be met. Suitable for clean lotion, edible oil, detergent, pickle food, etc.

PET Semi-Auto Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

This semi-auto stretch blow molding machine is the most cost effective solution for low level production of bottles, containers, and jars in small to large sizes.

Blow Molding Machine PBA Series

Categories : Horizontal Blow Molding Machines

These machines are high cycle pneumatic blow-molding machines, suitable for popsicles & wide variety small size bottles.

Continuous Co-Extrusion Blow Molding Machine (Multi Layer)

Categories : Automatic Blow Molding Machines

This series is specified for producing particular containers that are fully sealed, light resistant, heat resistant, anti-bacterial, durable, anti-static, corrosion resistant, non-toxic…etc.

Automatic Blow Molding machine- A Series

Categories : Automatic Blow Molding Machines

This type is the pneumatic-clamping blow-molding machine, suitable for making popsicle (ice-lolly) & various small-size bottles. Extrusion is driven by the inverter motor with pulley-drive gear box. Innovative design for double die head production. Mold clamping is driven by pneumatic system, available for upgrading to hydraulic-drive system (Option). Carriage movement is the swing movement for taking the finished products from the front of the machine. Independent electric control box with simple control panel. Simple-type blow molding machine, suitable for low and initial blow molding machinery investment.

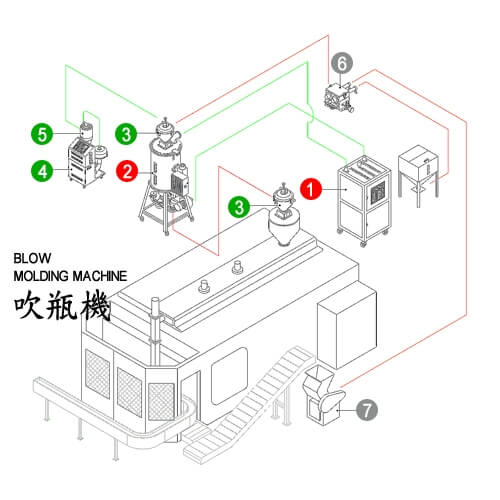

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Extrusion Blow Molding Machines

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

Medium Co-extrusion Blow Molding Machine – Double Station

Categories : Automatic Blow Molding Machines

Medium Co Extrusion - Continuous Type Blow Molding Machine Chen Way Machinery is well-known for its 20L three-layer blow molding machines. Three-layer co extrusion blow molding machines are the most popular choice for the edible oil export countries, and their productions range from 5L to 30L jerry can. The composition for three-layer products is usually as follows: The outer layer is composed of 15%-20% virgin material and masterbatches The inner layer is composed of 15%-20% virgin material. The middle layer is a combination of 60%-70% cost-effective regrind material and CaCO3 (no more than 30%) which reduces material cost by 10-12%. By contrast, only around 5%-7% CaCO3 can be added to single-layer jerry cans, which has no evident improvement over material savings.

Automatic Blow Molding machine- O Series

Categories : Horizontal Blow Molding Machines

Single Die Head or Double Die Heads and Single Station Type, Suitable for View Stripe Containers, Equipped with Auto Conveyor, and Leaking Tester for Quality Supervision.

PET Stretch Blow Molding Machine - The World's Most Energy Efficient Bottle Production Line (EM Standard Series)

Categories : Automatic Blow Molding Machines

Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Sretch Blow Molding Machine - TEM04S2-88

Categories : Automatic Blow Molding Machines

PET STRETCH BLOW MOLDING MACHINE-TEM04S2-88 FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - TEM06M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automaticalFEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.ly arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Blow Molding Machine - Wide Mouth Bottle

Categories : Horizontal Blow Molding Machines

Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - EX02MC-SH

Categories : Automatic Blow Molding Machines

● Blower power consumption for 1000 bottles: 2Wh. ● Air Compressor power consumption for 1000 bottles: 6 kWh compact space. ● Screw driven controlled by servo motor providing fast and smooth motion. ● Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating. ● Low-pressure air compressor will NOT be required due to high-pressure recovery system. ● High efficient air recovery system up to 45%.

Double Layer Accumulator Head Blow Moulding Machines

Categories : Extrusion Blow Molding Machines

Double Layer Accumulator Head Blow Molding Machines